Introduction

In the ever-evolving world of custom apparel production, Direct-to-Garment (DTG) printing has emerged as a game-changing technology. Known for its ability to produce vibrant, high-quality prints on fabric, DTG printing has revolutionized the way custom apparel is designed and manufactured. This article delves into the intricacies of DTG printing, exploring how it works, its benefits, and why it has become a preferred method in the custom apparel industry.

What is Direct-to-Garment (DTG) Printing?

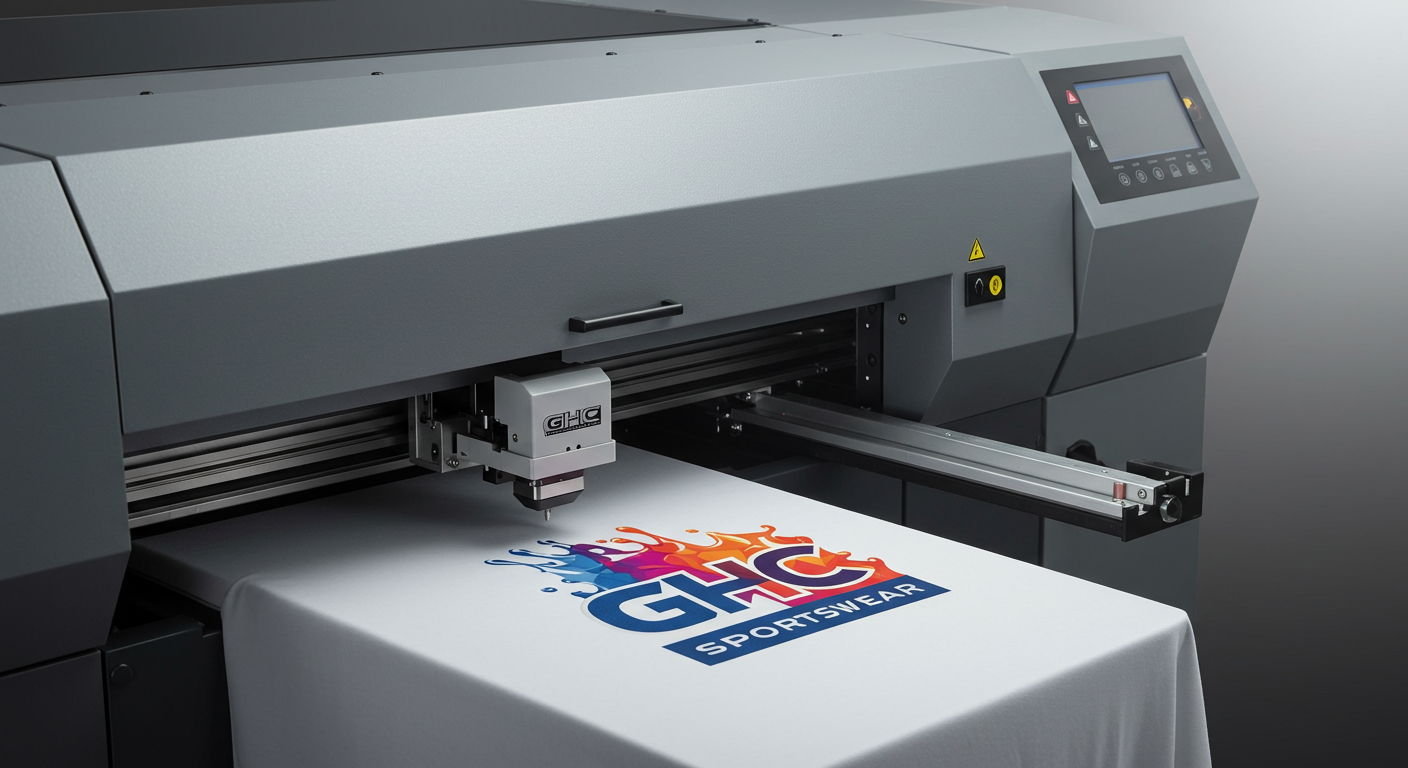

Direct-to-Garment printing is a method where digital designs are printed directly onto fabric using specialized inkjet technology. Unlike traditional printing methods like screen printing, which require the creation of screens or stencils for each color, DTG printing allows for the reproduction of complex, multi-colored designs with ease. The process is similar to how an inkjet printer works on paper but is adapted for textiles.

How Does DTG Printing Revolutionize Custom Apparel?

The DTG printing process begins with a digital file of the design, which is sent to a DTG printer. The fabric, typically a t-shirt or other apparel item, is pre-treated with a special solution that helps the ink bond with the fibers. This pre-treatment step is crucial for ensuring vibrant colors and durability.

Once the fabric is pre-treated, it is loaded onto the printer’s platen, a flat surface that holds the fabric in place. The printer then applies the ink directly onto the fabric in a series of passes, layering the colors to create the final image. The ink used in DTG printing is water-based, making it safe for the environment and soft to the touch.

After printing, the fabric is heat-cured, a process that sets the ink and ensures the design’s longevity. The result is a high-quality print that feels as soft as the fabric itself, with no noticeable texture or stiffness.

Advantages of DTG Printing in Custom Apparel Production

1. High-Quality Prints

One of the most significant advantages of DTG printing is the quality of the prints it produces. The technology allows for precise detail, making it possible to reproduce intricate designs and gradients that would be challenging with other printing methods. DTG prints are also known for their vibrant colors and smooth transitions, making them ideal for designs with multiple colors and fine details.

2. No Minimum Order Quantity

Unlike screen printing, which requires the creation of screens for each design, DTG printing has no minimum order requirements. This makes it an excellent option for small businesses, custom orders, or one-off designs. Whether you’re printing a single t-shirt or a small batch, DTG offers flexibility without compromising on quality.

3. Eco-Friendly

DTG printing is considered an environmentally friendly printing method. The water-based inks used in the process are free from harmful chemicals, making them safe for both the environment and the wearer. Additionally, DTG printing produces minimal waste, as there are no screens or stencils to dispose of after printing.

4. Quick Turnaround Time

Since DTG printing eliminates the need for screen setup and color mixing, it offers a faster turnaround time compared to traditional methods. Once the design is ready, printing can begin almost immediately, making it ideal for businesses that need to fulfill orders quickly.

5. Versatility

DTG printing is highly versatile and can be used on a variety of fabrics, including cotton, blends, and even some synthetic materials. This versatility allows for a wide range of custom apparel options, from t-shirts and hoodies to tote bags and caps.

Challenges of Direct-to-Garment (DTG) Printing

While DTG printing offers numerous benefits, it also comes with its own set of challenges.

1. Cost

One of the main drawbacks of DTG printing is the cost. The initial investment in a DTG printer can be significant, and the cost per print is generally higher than screen printing, especially for large quantities. However, for small runs and intricate designs, the cost is often justified by the quality and flexibility DTG offers.

2. Fabric Limitations

Although DTG printing works on a variety of fabrics, it performs best on 100% cotton. Blended fabrics, particularly those with high polyester content, may not hold the ink as well, resulting in less vibrant prints. Pre-treatment can help improve results on blends, but it may not achieve the same quality as printing on pure cotton.

3. Durability

While DTG prints are generally durable, they may not be as long-lasting as screen-printed designs. Repeated washing can cause DTG prints to fade over time, especially if the fabric is not pre-treated properly or if the ink is not fully cured. However, with proper care, DTG prints can maintain their quality for many washes.

Applications of DTG Printing in Custom Apparel

1. Small Businesses and Startups

DTG printing is particularly beneficial for small businesses and startups that want to offer custom apparel without investing in large inventory. The ability to print on demand means that businesses can fulfill orders as they come in, reducing the risk of overproduction and unsold stock.

2. Limited Edition and Personalized Designs

For businesses that offer limited edition or personalized designs, DTG printing is an ideal solution. The lack of minimum order requirements allows for the production of unique, one-off pieces, catering to customers who value exclusivity and personalization.

3. Event Merchandise

DTG printing is also popular for creating event merchandise, such as t-shirts for concerts, festivals, and charity events. The quick turnaround time and ability to print small quantities make it perfect for events where demand may fluctuate.

4. Fashion and Art

Artists and fashion designers are increasingly turning to DTG printing to bring their designs to life. The technology allows for the reproduction of complex artwork and patterns on fabric, offering designers a new medium to express their creativity.

The Future of Direct-to-Garment (DTG) Printing

As technology continues to advance, DTG printing is expected to become even more accessible and efficient. Improvements in ink formulations and printer capabilities will likely expand the range of fabrics that can be used, as well as enhance print durability. Additionally, as demand for eco-friendly production methods grows, DTG printing’s environmental benefits will become increasingly important.

Why DTG Printing is a Game-Changer for Custom Apparel

Direct-to-Garment (DTG) printing has undoubtedly revolutionized the custom apparel industry. With its ability to produce high-quality, detailed prints on demand, DTG has become the go-to method for businesses and individuals seeking flexibility, quality, and sustainability in their apparel production. While it comes with some challenges, the advantages of DTG printing make it a powerful tool for creating custom clothing that stands out in a crowded market.

As DTG technology continues to evolve, it will play a crucial role in shaping the future of custom apparel, offering even more possibilities for creativity and innovation. Whether you’re a small business owner, a fashion designer, or simply someone looking to create unique, personalized clothing, DTG printing is a technique worth exploring.

Additional Resources

For more insights into apparel printing methods, check out our detailed guide on Screen Printing vs. Sublimation.

To learn more about the impact of modern printing technologies on the custom apparel industry, visit the Direct-to-Garment (DTG) Printing Guide on Printing United.